How to know when it’s time to upgrade to a new roaster

For most roasters, there often comes a time when scaling operations is beneficial – or maybe even necessary. This could be for an endless number of reasons, including taking on a new wholesale client, launching an online store, or just a continuous increase in customer orders.

The decision to expand operations brings about many factors for roasters to consider, and one of the most important is investing in a new machine. Without a higher-capacity or more advanced machine, scaling a coffee business as sustainably as possible is quite the challenge.

So to learn more about how to know when it’s time to buy a new machine, I spoke to Niko Sunko, head roaster and green coffee buyer at Bell Lane Coffee in Mullingar, Ireland.

You may also like our article on how roasters manage their green coffee supplies.

Why scale your roastery?

Like any company, most roasteries aspire to grow. In terms of sales and other areas of business development, it’s rare that a coffee roaster would want to remain stagnant.

One of the biggest ways to expand operations is to take on a wholesale client. Naturally, when selling coffee to wholesale accounts, bulk orders will increase. In turn, the amount of coffee you need to roast will rise significantly.

It’s also worth noting, however, that the profit per bag of wholesale coffee will be smaller compared to direct-to-consumer orders. So to maintain or improve profits, the quantity of coffee sold also needs to increase, which usually means buying a larger-capacity machine. By roasting larger batches of coffee, operators can reduce labour costs and save time – and thereby increase the profit margin per wholesale bag.

But selling wholesale coffee may not be the most profitable or sustainable option for many roasters – and isn’t the only reason to scale operations. Opening an ecommerce store can be a more accessible way for roastery owners to sell more coffee – which means investing in a bigger roaster in the first place.

Beyond increasing business-to-business and business-to-consumer sales, roasters also need to ensure operations remain streamlined as they scale.

“When scaling our roastery, one of the advantages was strengthening our relationships with producers,” Niko says. “Importing larger volumes of green coffee is logistically easier for us, and also improves sales and revenue for both parties.”

So when should you scale operations?

First and foremost, there is no one-size-fits-all approach to expanding your coffee roasting business.

“It’s the ideal time to scale up your roastery when you have achieved stability in your operations and all aspects of production are running smoothly,” Niko suggests. “This often signifies that you have the knowledge and capabilities to handle production, sourcing, quality control, and logistics growth effectively.”

When a roastery experiences a continuous increase in the amount of coffee it’s roasting, it presents a good opportunity to assess whether it’s worth buying a larger machine.

Essentially, roasting higher volumes of coffee is a direct result of increased sales, which thereby indicates a rise in demand. If sales data from the past few years is available (and you can predict any trends or patterns) then a roaster should be able to project sales growth over a specific period of time.

Additionally, a roastery operator should also be able to estimate the amount of coffee to roast each week, as well as the number of hours it will take on their current machine. If the production and labour costs still break even while using that machine then it’s probably not time to upgrade to a new one.

Do you always need a larger roaster when expanding operations?

It’s certainly possible for a roaster to maintain operations while still using a small machine. But there are a few considerations to keep in mind.

Selling larger volumes of roasted coffee inevitably means more time spent operating the machine.

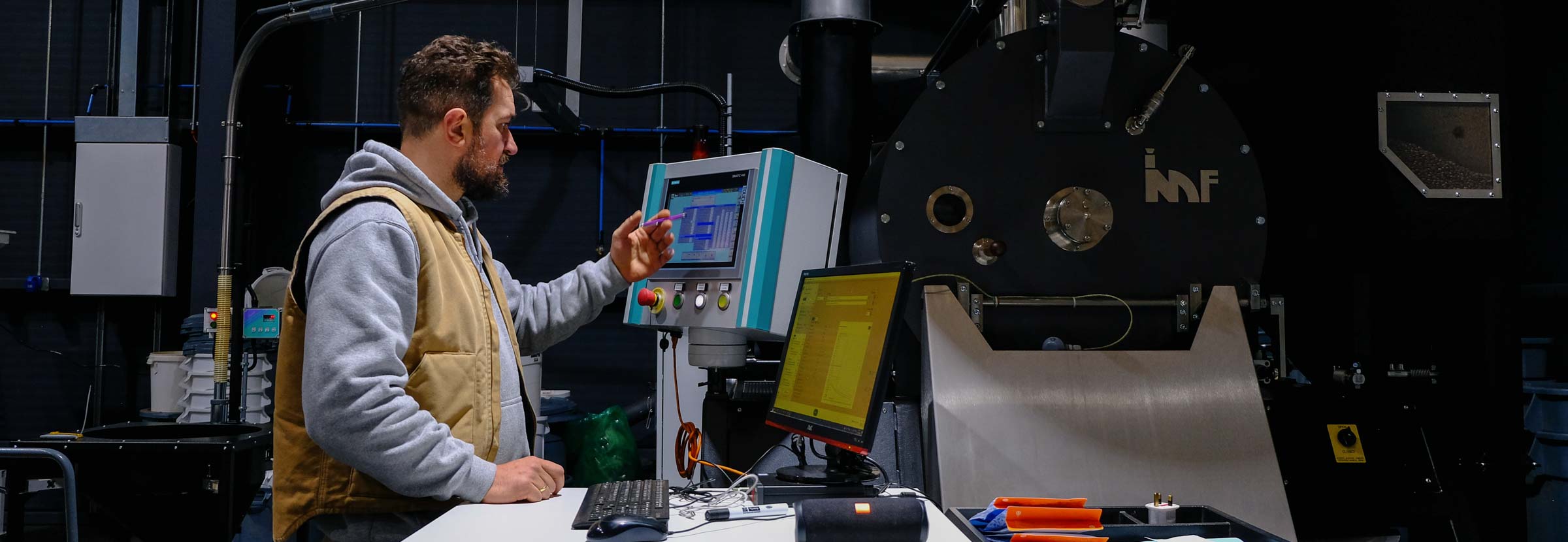

“Roasting smaller batches in succession to meet increased demand can be inefficient and labour-intensive,” Niko says, who uses an IMF roaster.

What’s more, consistency and quality are essential for roasting specialty coffee, so roasting smaller batches more often isn’t the most effective solution when sales start to increase.

“It will always be easier to consistently roast ten consecutive batches rather than 30,” he adds. “Investing in a larger machine often means you can exert more control over different variables, which is essential for maintaining consistency and quality as volumes increase.”

With this in mind, most manufacturers recommend that you don’t load roasters to more than 75% of their stated capacity per roast. On top of this, equipment manufacturers also recommend a limit as to how many batches you should roast per week on one machine.

For example, if a roaster can handle 5kg batches every 15 minutes, it doesn’t necessarily mean that you can fulfil 800kg of orders by roasting 160 batches per week without damaging your machine – not to mention the high energy costs.

Looking at different sized roasters

After choosing to buy a new machine, roasters first need to know which size will work best for them. This is largely based on how much coffee can be roasted per batch.

Smaller-sized roasters include home, sample, and small commercial machines. Many businesses start with smaller commercial roasters which have a 1kg to 3kg capacity.

However, if a business decides to scale, they are likely to need a bigger machine to keep up with an increase in orders – ranging from a 5kg to 15kg roaster.

Medium-sized commercial roasters, meanwhile, generally have a capacity between 15kg and 30kg. In many cases, these machines work best for most roasteries.

“For example, the IMF RM30 is a higher-capacity roaster that comes with integrated features such as a destoner and loader for green coffee,” Niko says.

A machine with a batch size of 30kg or more is considered a large roaster. Some of these models can even hold 70kg batches of coffee – which makes them much more suitable for large commodity-grade roasters.

“When scaling to establish a larger operation, the IMF RM60 has an even higher batch capacity,” Niko adds. “But it’s essential to work closely with an engineering and design team to plan your roastery layout, especially if you need to include packing lines for larger operations.”

Tips for investing in a larger roaster

Although upgrading the machine is just one aspect of expanding your roastery, it will have a significant effect on operations across the board.

Cost is almost always the main consideration. Roasters are one of the most expensive pieces of equipment that coffee businesses can buy, which has a huge impact on budgets.

A bigger machine will naturally also take up more space in a roastery, so you certainly need to account for enough room to ensure an efficient workflow.

Moreover, investing in a larger roaster typically means you will need more storage space for both green and roasted coffee. Packaging supplies, ventilation systems, storage containers, increased waste, and more staff working in the roastery should all also be accounted for when designing a larger space.

Energy supply is also important. When upgrading to a larger machine, keep in mind whether the roaster is powered by gas or electricity – and how this could affect your power sources. In these cases, it’s recommended to consult a professional roastery design company such as IMF.

Scaling roastery operations is generally a smart move for most coffee businesses. However, it must be done carefully and thoughtfully – and investing in a machine is one of the most important steps.

Prematurely upgrading your roaster too soon, however, can also bring about its own set of issues. Ultimately, it’s about weighing up the pros and cons, and taking all factors into consideration.

Enjoyed this? Then read our article on how roasters store and transport roasted coffee safely and effectively.

Photo credits: Bell Lane Coffee

Perfect Daily Grind

Please note: IMF Roasters is a sponsor of Perfect Daily Grind.

Want to read more articles like this? Sign up for our newsletter!